Supplier Base

We provide complete ready-to-use assemblies to our esteemed customers, outsourcing special processes of the components through approved suppliers across South India, offering a one-stop solution.

➤ 40+ Approved suppliers & Service Providers for special processes.

➤ NABL Approved Laboratory for Chemical, Mechanical, Micro, Macro, Grain size, and Intergranular corrosion testing.

➤ Ultrasonic Testing, Magnetic Particle Inspection, Penetration Test, Radiography Test, Positive Material Identifier.

➤ Balancing up to 4 Tons of Equipment.

➤ Heavy Machining - CNC, VMC, HMC, Surface Grinding, Cylindrical Grinding, Owning, etc.

➤ Plating — Zinc Plating, Magnesium Plating, Hydrogen Embrittlement & Blackening.

➤ Thread Rolling, Head Forming, Sparking, Punching.

➤ Quenching & Tempering, Case Carburizing, Induction Hardening, Nitriding.

➤ Gear Cutting, Gear Grinding.

➤ Laser Marking, Dot Pin Marking, etc.

Infrastructure and Capabilities

➤ Holding a huge network of suppliers for parts ranging from 1 kg to 2000kg out of forging, Casting various material grades.

➤ In-House Turning, Milling, facilities with Fixtures, Special Taps & various Gauges with calibration Instruments.

➤ Associated with Specialized heat treatment plants for various Metallurgical operations, NABL-approved testing facilities, Metal surface coating plants, CMM measuring facility.

➤ Comprehensive design and manufacturing solutions.

➤ Efficiency: Implementation of Lean manufacturing systems.

➤ Outcome: Faster delivery of components at competitive prices, ensuring uncompromised quality, and developing adoption of new manufacturing process to achieve minimal costing at best quality.

Empowering Diverse Sectors

Our components are integral to mission-critical operations across numerous industries.

We design and deliver high-precision parts that perform under extreme conditions and meet rigorous compliance standards.

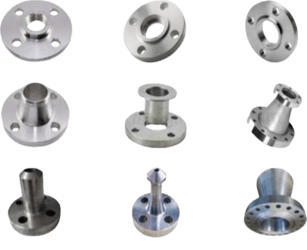

Oil & Gas – Durable components for exploration, refining, and transport operations.

Hydraulics – Efficient parts for fluid control systems and power transmission.

Automotive – Precision parts for engines, suspensions, and custom assemblies.

Railways – Long-lasting components for rolling stock, tracks, and safety systems.

Power Sector – Components for coal-powered, hydro, and renewable energy systems.

Agriculture – Innovative solutions for modern farming equipment and implements.

We support both standard and made-to-order production, helping our clients stay ahead in their respective fields.